The 185000 m² production facility which is located in the western extremity of Anatolia will have produced around 2000 units by end of this year, of which is mainly curtainsider trailers. The plant's capacity is annual production of approximately 10000 units, which will be sold on the Turkish market and in the markets around Turkey (Turkish states, North Africa, Iran, Iraq).

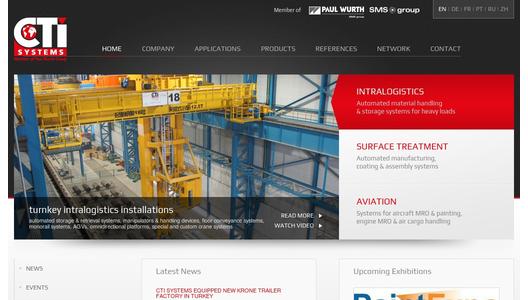

The plant design started with the layout of the complete facility (production and administration building and outside areas). After the design phase, CTI Systems assisted its customer with selection of the construction company in Turkey. CTI was responsible for supervision of the interfaces between the building, the machinery and all automated processes during the erection pe-riod of the facility. The plant is equipped with the latest systems to meet the customer's own quality requirements and those of their clients to deliver first-class products.

In autumn 2012 when the first trailers came off the production line, The Managing Director of the renowned trailer manufacturer explained: "We wanted to start with a small quantity of around 50 trailers per week. We have been slowly ramping up production and are very pleased that all the processes are running properly." Production was originally planned to commence in 2009 but owing to the global financial crisis, this was delayed.

The system starts by the shotblasting process at the end of which the chassis are cleaned from remaining shots through the semi-automatic turning station. From there the chassis or smaller parts are transferred to the input area which is connected to a fully automatic surface treatment process of pretreatment, cathodic e-coating, heat treatment and powder coating for the best corrosion protection. The transfer through the coating processes and to the intermediate buffer zones is ensured by CTI provided automatic transfer bridges, shuttles and conveyors.

Linked to the surface treatment processes is the final assembly line with all working stations to a completed trailer. CTI Systems provided all handling and transport devices from the semi-automatic turning station, patent track monorail system with transfer bridges and monorail conveyors to the tilting station and floor turntable.

Again this installation demonstrates CTI Systems' capabilities to fully provide automatic manufacturing and coating lines. Moreover all warehouse systems run with the CTI self-developed Warehouse Management System software. And the manufacturing operations can be controlled by the CTI Manufacturing Execution System software with link to the ERP system.