The new 18500 m² (200000 ft²) state-of-the-art dip and powder-coat paint facility consolidates AGCO Hesston Operations' paint stations from two operations into one streamlined, efficient building.

Parts for all products manufactured in Hesston will be painted and finished there before being assembled into final products. Nearly 75% of parts will go through the 15-step dipline for pre-treatment, nanocoating and cataphoretic coating. After curing of the E-coat the parts are powdered in automatic powder booths and cured after on in order to get a high-performance corrosion- and weather-resistant finish comparable to that used in the automotive industry. In order to reduce energy and to adapt curing temperatures and curing times to the parts and loads, 20 batch ovens are used to cure the E-coat and the powder. Not used ovens could be switched off when not required.

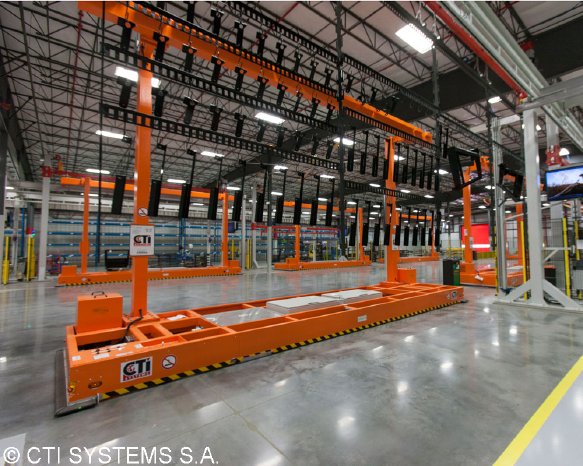

The entire paint shop is equipped with automated floor-based and overhead material handling devices from CTI Systems for connection of the different steps of the processes, including tank line transfer bridges, tank line bridges, distribution transfer bridges, elevators as well as loading/unloading stations. The system for the tank line can handle part sizes up to 8.5 x 3 x 3 m (28 x 10 x 10 ft) and up to a weight of 2950 kg (6500 lbs). For the wet paint line, the system can handle part sizes up to 15.9 x 3 x 3 m (52 x 10 x 10 ft) and up to a weight of 2270 kg (5000 lbs).

The entire material flow process is automated and under control of software developed by CTI Systems, to ensure process visualization and data acquisition, with connection to the customers ERP/MES system.

In the spacious load and unload center, parts are placed on load bars and transported to the paint line by 18 un-manned automated guided vehicles (AGVs) with full omnidirectional capabilities and which are programmed to follow a series of magnets in the floor as they move parts into the paint facility. This high level of automation reduces employee exposure to the paint process, increases productivity and improves parts flow through the paint center and back to the assembly lines.

The e-coat and powder paint processes also offer efficiency and environmental benefits as more than 95% of powder paint is transferred to the parts and the remainder is fully captured in the paint process.

Furthermore, process equipment benefits of an energy management system reducing energy consumption considerably during process.

This new cataphoretic coating and powder paint facility providing a thorough, consistent, durable finish is the most advanced and extensive coatings application center in the North American agricultural equipment industry today, and will allow AGCO to provide its customers with the highest-quality haying and harvesting equipment products possible.

This successfully accomplished project again emphasises CTI's excellent capabilities as turnkey system provider in the surface treatment and intralogistics branch. With core competencies in project planning and engineering, CTI Systems provides the best and most innovative solutions yielding the maximum benefit in terms of cost and productivity, but also taking individual circumstances into account. With CTI's knowhow in implementing turnkey systems, new installations run with their full potential within the required schedule.