- Detailed instructions for CT 881 WP1 timing belt kit in a Ford Fiesta V MY 2004 (JH_JD_) 1.4-liter 16 V with engine code FXJA

- ContiTech shows how to avoid errors when changing belts

The manufacturer recommends changing the

- timing belt every 160,000 km/10 years

- ancillary unit belt (ELAST) every 160,000 km/10 years

The labor time is 2.8 hours.

The labor time for the ancillary unit belt is 0.6 hours.

Tip: The multi V-belt must be changed at the same time as the timing belt. The multi V-belt must not be re-fitted once it has been removed.

Fitters need the following special tools for the procedure:

The tools can also be found in ContiTech¹s Tool Box V04.

- Locking tool for crankshaft OE (303-748), Tool Box V04/16

- Alignment tool for camshaft OE (303-376B), Tool Box V04/21

- Counterhold OE (205-072), Uni Tool Box/3

Identify the vehicle using the engine code.

Disconnect the vehicle battery. Do not turn the crankshaft and camshaft once the timing belt has been removed. Turn the engine in the normal direction of rotation (clockwise) unless otherwise specified.

Turn the engine only at the crankshaft sprocket and not at other sprockets. Only carry out checks and adjustments when the engine is cold. Avoid contact between the belt and harmful substances, such as engine oil or coolant.

Comply with all the tightening torques specified by the vehicle manufacturer.

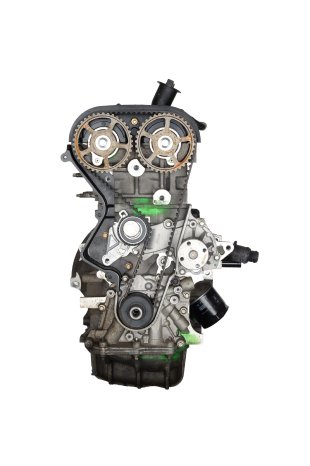

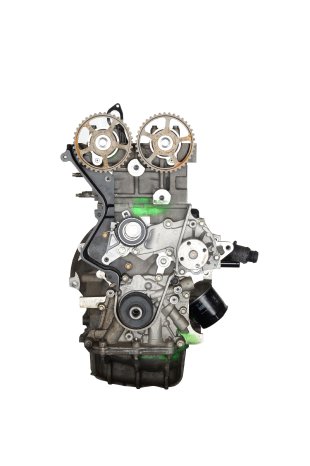

Removal: front right wheel, ancillary unit belt, spark plugs, cylinder head cover, crankshaft belt pulley, drive pulley for coolant pump, power steering fluid reservoir and coolant expansion reservoir, alternator, front engine mounts with bracket (support engine using vehicle jack),upper and lower timing belt guards (Figs. 1 and 2).

Removal camshaft belt:

- Set valve timings to just before TDC mark of cylinder 1.

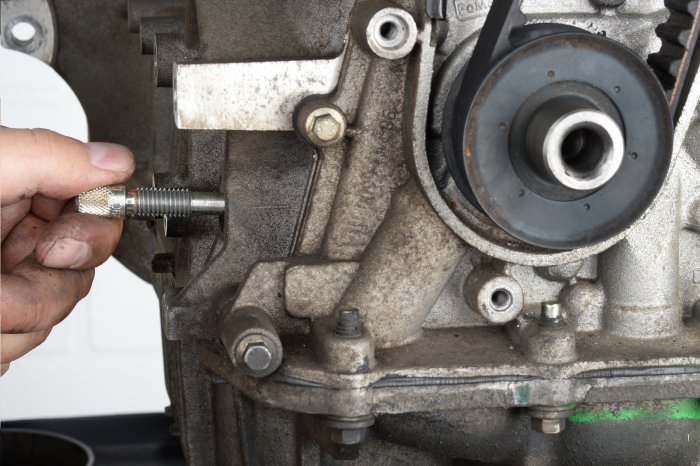

- Unscrew screw plug at left above oil pan and insert locking tool for crankshaft OE (303-748), Tool Box V04/16 (Figs. 3, 4 and 5). Keep turning crankshaft slowly against locking tool stop.

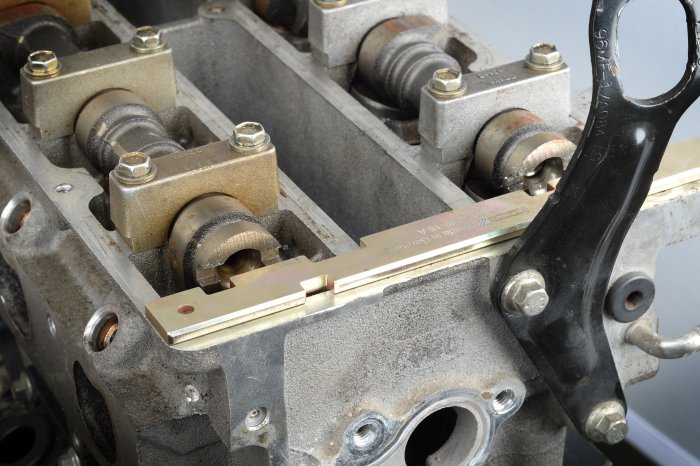

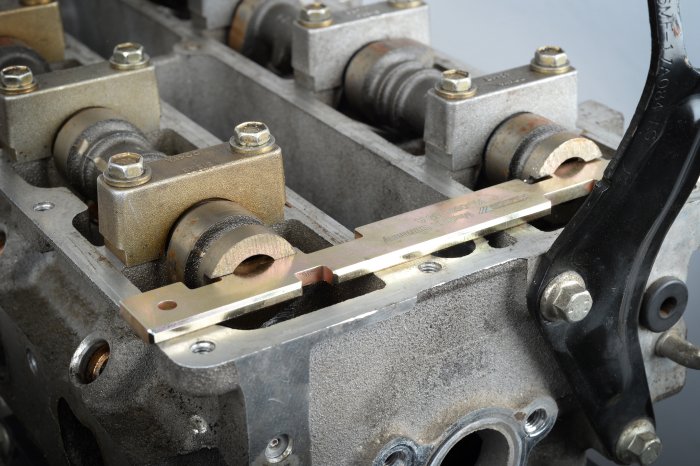

- Insert alignment tool for camshaft OE (303-376B), Tool Box V04/21, into camshaft grooves at rear (Figs. 6 and 7).

- Unscrew tensioning pulley bolts and remove timing belt.

- Fit new components from timing belt kit. Check remaining components such as camshaft sprocket and crankshaft sprocket for damage (Fig. 8).

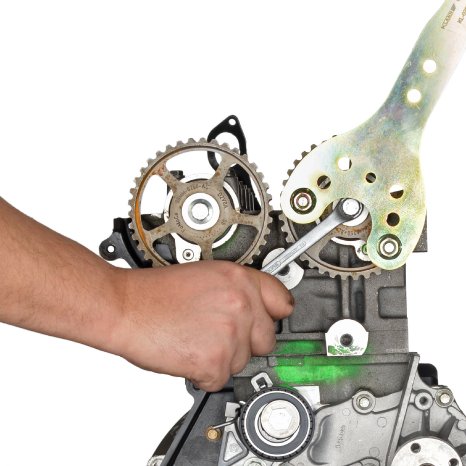

- Remove locking and alignment tools and loosen camshaft sprockets using counterhold OE (205-072), Uni Tool Box/3 (Fig. 9). Change both bolts (new bolts are contained in kit).

- Insert locking and alignment tools again.

- Hand-tighten camshaft sprocket bolts so that camshaft sprockets can just be turned.

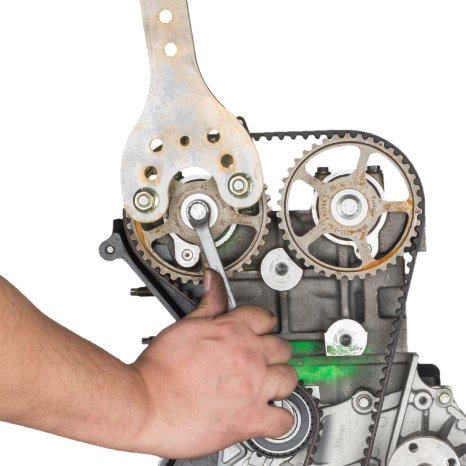

- Fit timing belt counterclockwise, starting at crankshaft sprocket (Fig. 10). Take care to ensure that timing belt is not kinked during fitting! Timing belt must be tight between sprockets on tight side.

- Fit crankshaft belt pulley and lower guard using supplied new bolt and remove tensioning pulley locking pin. Tension is automatically set by tensioning pulley. No further settings at tensioning pulley are necessary! Tighten tensioning pulley bracket plate to 20 Nm.

- Remove locking and adjustment tools from crankshaft and camshaft.

- Tighten camshaft sprockets to 60 Nm using counterhold OE (205-072), Uni Tool Box/3 (Fig. 11).

- Turn engine through 2 revolutions in direction of engine rotation.

- Set valve timings to TDC mark of cylinder 1 and check. Setting as for items 1 and 4 of Removal above. If locking and adjustment tools cannot be inserted into crankshaft and camshaft, timings must be set again. Engine can be damaged if timings are not set correctly!

- Remove locking and adjustment tools from crankshaft and camshaft.

- Assembly and finalization in reverse order to removal.

Bolts for belt pulley for coolant pump 24 Nm

M 12 crankshaft bolt (central bolt), 40 Nm + 90°

Timing belt guard 9 Nm

Engine block screw plug 20 Nm

Engine mount to body 48 Nm (use new nuts)

Engine mount to engine support 48 Nm (use new nuts)

Engine mount locking bolts 55 Nm

Spark plugs 15 Nm

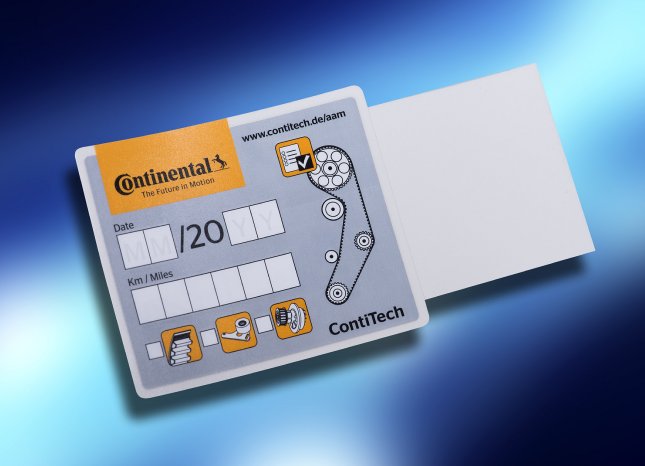

13. Record changing of original ContiTech timing belt on sticker supplied and stick this in engine compartment (Fig. 12).

Then carry out a test run or test drive.