- Detailed instructions for Fiat Doblò panel van/station wagon (263) 1.6 D Multijet

- ContiTech shows how to avoid errors when changing belts

Large numbers of the 1.6 D Multijet diesel engine are installed in Fiat vehicles. Significant errors are frequently committed when changing the timing belt. To ensure that the belt change operation goes smoothly, the ContiTech Power Transmission Group provides fitters with a detailed installation guide. In this, ContiTech experts provide a step-by-step explanation of the correct change procedure on a Fiat Doblò (263).

The manufacturer recommends inspecting and, if necessary, changing the timing belt at 150,000 km or after five years for vehicles without a particulate filter. In the case of vehicles with a particulate filter, inspection after 140,000 km or five years is recommended.

Tip: Replace the tensioning pulley, idlers and water pump at the same time as changing the timing belt.

The labor time is 2.7 hours.

Fitters need the following special tools for the procedure:

1. Cam shaft locking tool – OE no. 1870836000

2. Cam shaft locking tool – OE no. 1870896900

3. Flywheel locking tool – OE no. 1860898000

4. Crankshaft locking tool – OE no. 2000003000

5. Counterhold – OE no. 1870815000

Preparatory work:

Identify the vehicle using the engine code.

Disconnect the vehicle battery.

Do not turn the crankshaft and camshaft once the timing belt has been removed.

Turn the engine in the normal direction of rotation (clockwise).

Turn the engine ONLY at the crankshaft pulley and not at other pulleys.

Comply with all tightening torques.

Jack up and prop the front of the vehicle.

Remove: engine cover, engine compartment underpanel, front right wheel, engine compartment underpanel right, ancillary unit belt plus tensioning pulley and idler of ancillary unit belt, air intake hose from air filter housing and air filter housing, air intake pipe from turbocharger, air flow sensor, engine mount bolts, engine mount and timing belt guard

Locate engine support beam.

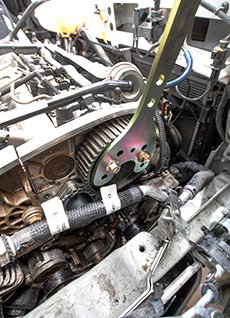

Removal – camshaft belt:

1. Remove cover from flywheel and insert locking tool (186089000) into flywheel (Figs. 1a-d).

2. Unscrew crankshaft pulley bolts and remove crankshaft pulley.

3. Remove locking tool (186089000) from flywheel.

4. Set valve timings to mark.

5. Disconnect plug of fuel pressure sensor so that bolt can be removed from camshaft housing (Fig. 2). Unscrew bolt from crankshaft housing.

6. Insert locking tool (1870896900) into camshaft housing (Figs. 3a and 3b).

7. Remove bolt from crankcase cover left next to crankshaft pulley and place gauge (2000003000) on crankshaft pulley (Fig. 4).

8. After checking the valve timing setting, gauge can be removed again and tensioning pulley can be released by loosening tensioning pulley bolt. Timing belt can now be removed.

Installation – camshaft belt:

1. Fit new tensioning pulley and idlers.

2. Loosen camshaft pulley by mounting counterhold (1870815000) on camshaft pulley and loosening camshaft bolt (Fig. 5).

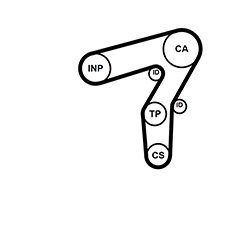

3. Camshaft locking tool (counterhold) (1870836000) is inserted (Fig. 5).

4. Fit timing belt on crankshaft pulley, starting clockwise. Take care to ensure that timing belt is not creased during fitting! Timing belt must be tight between pulleys on tight side! Markings on timing belt must align with markings on camshaft pulley, crankshaft drive pulley and high-pressure pump pulley (Figs. 6a and 6b).

5. Then place gauge (2000003000) on crankshaft pulley again, secure with bolts (Fig. 7) and check valve timings.

6. Press tensioning pulley spring down using screwdriver until tensioning pulley pointer is aligned with bore (Figs. 8a and 8b).

7. Tighten tensioning pulley bolt, 23-28 Nm.

8. Retighten bolts of camshaft pulley to required torque (Fig. 9) using counterhold (1870811500). Tightening torque: 28-31 Nm + 40°.

9. Remove locking tools.

10. Turn engine through two revolutions in direction of engine travel. Set engine to TDC cylinder 1. Insert camshaft locking tool and crankshaft pulley gauge. If locking tool cannot be inserted, correct valve timings. Check timing belt tension again.

11. Remove locking tools and gauge, locate and tighten screw plug with the new o-ring in camshaft housing again (13-16 Nm). Remove holding tool and fit components in reverse order of removal.

12. Fitting: timing belt guard, crankshaft pulley (tightening torque 23-28 Nm), ancillary unit belt plus tensioning pulley and idler for ancillary unit belt, engine mount bolts and engine mount, air intake hose from air filter housing and air filter housing, air intake pipe from turbocharger, air flow sensor, engine cover, engine compartment underpanel, front right wheel and engine compartment underpanel right.

13. Record changing of original ContiTech timing belt on sticker supplied and stick this in engine compartment (Fig. 10).

Then carry out a test run or test drive.