For use on highly thermally or mechanically stressed locations of cores of all casting materials or for poorly compacted sand particles in molds, the use of SILICO® IM 801 (in a can) guarantees a smooth, casting surface free of metal penetration. The spray process ensures a selective and clean application that guarantees efficient deployment of the coating (picture 1).

SILICO® IM 801 can also be used efficiently for poorly compressed sand components in moulds. The solid-rich, highly refractory alcohol-based coating with strong impregnation permeates deep into the substrate of the mould material. In this way, binder bridges are covered and porous spaces in the first three to five grain layers filled. Penetration is reduced and an enormous improvement in the casting surface achieved. Cleaning and grinding work per cast part can be reduced significantly through pre-treatment of the affected areas. (picture 2).

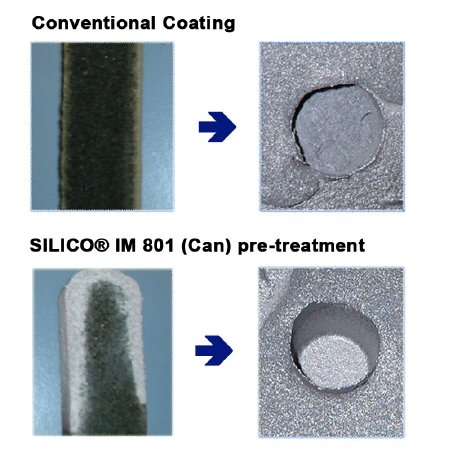

The pictures below show how impressive the difference is between using a conventional coating and the SILICO® IM 801 impregnation coating, which permeates and seals several millimeters into the material. This makes it impossible for metal to penetrate the material.

These results were produced in the Ashland-Südchemie-Kernfest research and technology center. By combining theoretical knowledge with practical experience, and by engaging in a dialog with the customer, the research team develops new products and applications which are as innovative as they are efficient. Both now and in the past, this provided reaction mechanisms in the coatings and information about reactions of the coatings with the moulding material or adjoining metal. Based on these findings, Ashland-Südchemie-Kernfest developed high-performance coatings which offer great benefits to foundries in terms of casting quality and further processing. They contribute to preparing the industry for the future.

You can find further information about the complete KERNTOP coatings program at www.ask-chemicals.de.

Capture:

Picture 1: Selective application of impregnation coating SILICO® IM 801 from the can

Picture 2: Casting result with / without application of SILICO® IM 801