ASK Chemicals Metallurgy GmbH has, with the development of the SMW insert™, now succeeded in developing an inoculant that gives foundries a decisive procedural advantage in the production and development of better quality cast parts with thicker walls made from cast iron with nodular graphite.

The mold inoculant SMW insert™ excels, in this connection, due to a wide range of advantages. The mold inoculation with the cerium- and bismuth-based SMW insert™ prevents chunky graphite by neutralizing disruptive elements. A further advantage of the inoculation process is that it takes place without oxygen. Oxide and sulfide formations as well as oxidic impurities, such as slag, are thus minimized. The graphite degeneration is prevented due to the very late inoculation of the iron. This process ensures an optimal, uniform inoculation of the entire cast part during mold filling. The nodule count can be increased up to 400 nodules per mm2 and the nodule size reduced. The mechanical properties, e.g. strength and toughness, are optimized depending on the wall thickness. Additional procedural advantages of the mold inoculant SMW insert™ are due to the ability to precisely calculate the required dose. The use of an additional metal stream inoculation device can thus be dispensed with.

Use of SMW inserts™

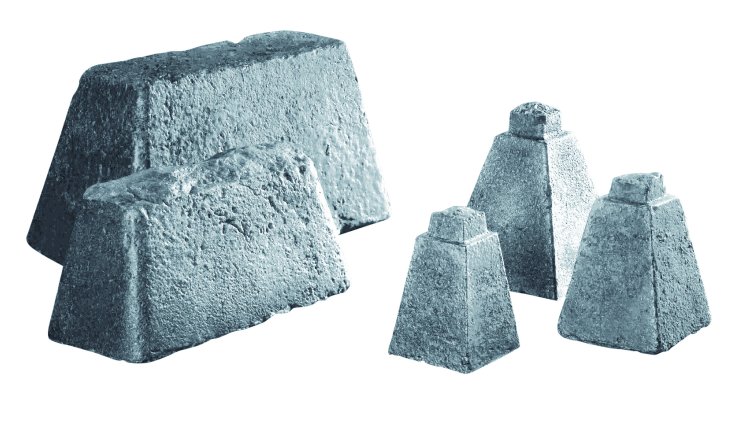

The SMW insert™ can be used depending on the trace element content. The recommended amount to be added is in the region of up to 0.2%. We recommend that it be used in combination with the already established mold inoculant Germalloy™ where the influence of trace elements is lower. Depending on the trace element content as well as for component-based reasons, the ratio can, for example, be 0.10% SMW insert™ and 0.10% Germalloy™ for an inoculant addition of 0.20%. All previously known P inserts, P 300 to P 30, are also available as SMW inserts™ (Figure 1).

The SMW insert™ can be used in combination with a preconditioning agent, e.g. VL (Ce) 2 and with a cerium-free and/or low-content-cerium FeSiMg master alloy, e.g. VL 63 O or VL 63 M 3. Small mold inoculation bodies should, in all cases, be installed in the pouring basin as "starters" – e.g. P 300, P 500 and/or P 800 – in order to ensure efficient and prompt inoculation. It is thus ensured that the cast iron that flows in first – which can solidify near the risers – does not have any chunky graphite and the inoculation effect is realized right from the start of the mold filling.

In addition to the quality aspects, there are also economic reasons for using these mold inoculants according to Dr. Sven Uebrick, Global Product Manager ASK Chemicals Metallurgy. These effects have been investigated in detail in extensive tests by ASK Chemicals Metallurgy GmbH and verified in practice.